Which industries benefit most from using optical measurement systems?

Which industries benefit most from using optical measurement systems?

Blog Article

The Duty of Optical Dimension Solutions beforehand Metrology Methods

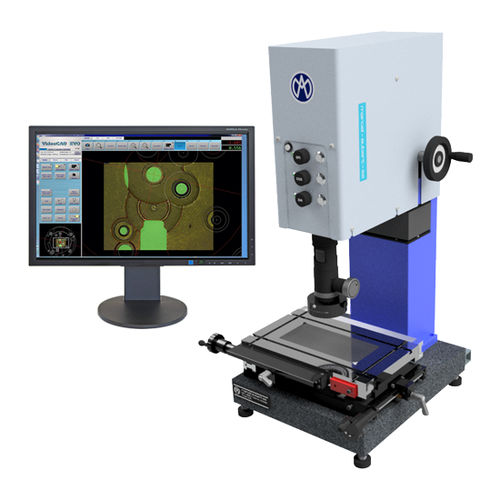

Optical dimension systems have actually transformed width, bringing a degree of accuracy that was when unbelievable. You could be surprised to learn how these innovations, based on fundamental concepts like representation and disturbance, are used across numerous sectors. Their non-contact capabilities not just boost precision however likewise improve processes. As you check out additionally, you'll find how these systems are forming the future of dimension and quality assurance.

The Evolution of Width: A Historical Point Of View

As you explore the background of metrology, you'll locate that its advancement reflects humankind's quest for accuracy and standardization. From old people using body components as units of dimension to the advancement of standard weights and steps, each step reveals our desire for accuracy. The Egyptians constructed the pyramids utilizing precise dimensions, while the Romans advanced engineering with their innovative measuring tools.

Throughout the Renaissance, scientific developments moved the focus towards more empirical methods, leading the way for modern-day metrology. The intro of the metric system in the late 18th century marked a considerable milestone, developing global standards. Throughout the 20th century, technical advancements additionally transformed metrology, making it possible for highly precise dimensions in numerous areas.

Today, assessment remains to evolve, integrating electronic modern technology and automation. This background highlights not just the significance of measurement however additionally our unrelenting pursuit of enhancing precision and consistency in our increasingly intricate world.

Principles of Optical Measurement Systems

Comprehending the concepts behind optical dimension systems is crucial for accurate results in metrology. You'll intend to think about fundamental optical principles, measurement precision variables, and effective system calibration methods. Each of these aspects plays a crucial function in ensuring your measurements are exact and reliable.

Fundamental Optical Principles

While discovering optical measurement systems, you'll come across fundamental optical principles that develop the foundation of precise information purchase. Light acts in predictable means, and comprehending these behaviors-- like diffraction, representation, and refraction-- is important for reliable dimensions. By understanding these principles, you'll be outfitted to leverage optical innovations effectively, paving the means for developments in width and ensuring your dimensions are both reputable and repeatable.

Measurement Precision Factors

To accomplish high dimension accuracy in optical systems, several factors come right into play, affecting the integrity of your results. Top quality lenses and detectors decrease aberrations and noise, ensuring your dimensions are accurate. By dealing with these elements, you can boost the general performance of your optical dimension systems, leading to even more exact and reliable outcomes in your assessment applications.

System Calibration Techniques

Achieving high dimension accuracy is just component of the formula; appropriate system calibration strategies are similarly vital in optical dimension systems. To assure your system provides trustworthy outcomes, you need to regularly adjust it utilizing standard recommendation products. Start by readjusting the optical elements, like lenses and mirrors, to decrease systematic errors. Next off, employ recognized dimensions to verify the system's outcome and make necessary modifications. It's additionally important to represent environmental elements-- temperature and moisture can influence measurements. Carry out a regular calibration timetable to maintain consistency gradually. Record all calibration treatments and outcomes; this will aid you track efficiency and resolve any type of drift in precision. With these strategies, you'll boost the integrity of your optical measurement system.

Key Technologies Behind Optical Measurement

Optical measurement systems count on numerous vital modern technologies that boost accuracy and effectiveness in metrology. One important technology is interferometry, which utilizes the disturbance of light waves to determine small displacements and surface irregularities with extreme accuracy. You'll likewise find laser scanning systems, which record thorough 3D information of objects quickly, making them vital for dimensional analysis.

Additionally, CCD and CMOS sensing units play a considerable duty in transforming light into electric signals, enabling for high-resolution imaging and precise dimensions. Advanced algorithms for photo handling further enhance measurement precision by evaluating data in actual time, straining noise and improving functions.

Finally, optical fiber offer versatility and the capability to gauge in tough environments while keeping signal integrity. By leveraging these modern technologies, you can accomplish superior lead to your metrology tasks, guaranteeing that your dimensions are both exact and reputable.

Applications of Optical Dimension in Market

As industries significantly demand precision and performance, the applications of optical measurement systems have actually become crucial across numerous industries. In production, these systems aid you keep an eye on dimensions and tolerances in real-time, making certain quality assurance without taxing hands-on checks. In the auto industry, optical measurements help in aligning elements with accuracy, boosting safety and efficiency.

In electronic devices, you're using optical methods to check minute features on circuit boards, finding issues that might lead to failures. The aerospace industry gain from non-destructive testing techniques, enabling you to examine products and elements without endangering their honesty.

Optical dimension additionally plays an essential duty in fabrics, ensuring textile measurements satisfy specific requirements. optical measurement. With their ability to offer high-resolution information swiftly, these systems equip you to make educated decisions, simplify procedures, and eventually drive advancement throughout your sector

Enhancing Precision and Performance in Dimensions

When you think of improving precision in measurements, accuracy in your dimension methods is crucial. By simplifying these processes, you can achieve quicker outcomes without giving up high quality. Allow's discover exactly how adopting advanced optical measurement systems can elevate both precision and effectiveness in your work.

Accuracy in Dimension Strategies

Precision in measurement strategies is crucial for achieving trusted outcomes in metrology, especially since small inconsistencies can result in substantial mistakes. By making use of advanced optical dimension systems, you can boost the precision of your measurements. These systems provide high-resolution information that help you discover even the least variations in measurements. When you take on these innovations, you minimize unpredictabilities and improve repeatability in your procedures. Additionally, exact dimensions enable you to maintain top quality control, guaranteeing that items meet rigid specs. This not just increases your reliability yet additionally enhances customer contentment. Buying accuracy measurement tools eventually leads to raised performance, decreased waste, and enhanced production cycles. Welcoming here these techniques will transform your technique to width, producing impressive results.

Improving Measurement Procedures

To improve precision and performance in measurements, enhancing your measurement processes is vital. Beginning by taking on optical dimension systems that offer real-time data, lowering the moment invested in hands-on recording. These systems usually integrate flawlessly with existing software application, enabling you to automate information collection and analysis.

Following, systematize your dimension methods. By implementing constant procedures, you minimize variability and boost repeatability. Do not fail to remember to consistently adjust your equipment to guarantee its accuracy.

The Influence of Optical Dimension on R & D

As scientists undertaking to push the boundaries of advancement, optical dimension systems have become essential devices in the development process. These systems supply you with precise, real-time information that boosts your ability to examine intricate materials and structures. In different areas, from biotechnology to aerospace, you depend on optical measurements to enhance and enhance layouts product performance.

With high-resolution imaging and non-contact techniques, you can lessen example disruption, enabling more accurate results. This capability to record minute information increases your R&D cycle, allowing you repeat designs swiftly and efficiently. Additionally, optical measurement fosters cooperation throughout self-controls, as the information generated is commonly conveniently interpretable and shareable.

Eventually, integrating optical measurement systems right into your study not only boosts productivity but additionally grows your understanding of the phenomena you study. By leveraging these innovative strategies, you're much better furnished to introduce and stay ahead in an affordable landscape.

Future Patterns in Optical Measurement Solutions

With the rapid advancement of modern technology, you're most likely to see substantial changes in optical measurement systems that will certainly redefine their application throughout different markets. You'll discover an approach enhanced automation and integration of synthetic knowledge, enabling real-time data evaluation and boosted precision. Miniaturization is another fad; compact devices will certainly allow measurements in tighter rooms, making them perfect for fields like aerospace and biomedical applications.

Anticipate to see systems that can operate in difficult atmospheres, providing trusted measurements in extreme problems. As these technologies assemble, you'll find that optical measurement systems not only enhance accuracy but additionally streamline process, ultimately driving innovation and effectiveness in your tasks.

Regularly Asked Concerns

Exactly How Do Optical Dimension Solutions Contrast to Traditional Measurement Techniques?

Optical measurement systems use higher precision and faster results compared to conventional strategies. You'll locate they catch more data points properly, decreasing human error and increasing reliability, making them a preferred option in various applications.

What Industries Advantage The Majority Of From Optical Dimension Solutions?

You'll discover industries such as aerospace, automotive, and electronic devices benefit most from optical measurement systems. These markets rely on exact measurements to ensure quality and performance, enhancing effectiveness and minimizing costs with innovative technology.

Are Optical Dimension Equipments Expensive to Implement?

Optical measurement systems can be expensive to execute, but their accuracy and effectiveness typically justify the expense. Purchasing such technology can bring about substantial long-lasting financial savings and improvements in top quality across various applications.

What Abilities Are Needed to Operate Optical Measurement Solutions?

To run optical dimension systems, you'll require strong analytical abilities, attention to detail, and efficiency in software application devices. Knowledge with optics and an understanding of measurement principles will additionally enhance your efficiency and efficiency.

Just How Do Ecological Variables Influence Optical Measurements?

Environmental elements like humidity, temperature, and air quality can misshape optical measurements. You'll see variations in accuracy as a result of Click Here light interference or refraction. optical measurement system. Maintaining stable problems is necessary for specific and dependable optical dimension results

Verdict

In recap, optical measurement systems are changing assessment by supplying unmatched accuracy and effectiveness. As you official statement check out future fads, you'll see just how the combination of AI and automation will continue to boost dimension methods, driving development and boosting top quality control.

Accomplishing high dimension precision is only part of the formula; appropriate system calibration strategies are equally vital in optical dimension systems.When you assume about improving precision in measurements, precision in your measurement strategies is important. By utilizing innovative optical dimension systems, you can enhance the accuracy of your measurements.To improve accuracy and effectiveness in dimensions, streamlining your measurement processes is essential. How Do Optical Dimension Equipments Compare to Traditional Measurement Techniques?

Report this page